|

YUYAO ERM RUBBER & PLASTIC CO., LTD.

|

Gold Index: 34713

You are here: home > Products Description > New design oil seal for high speed motor of soy milk maker and juice extrator

Product (519)

-

laboratory Products

(69)

- Ptfe siliconce septa (69)

-

Automotive seal

(391)

- oil seal (391)

- PTFE molded machine (12)

-

Molded rubber products

(19)

- rubber gasket (19)

- Others (28)

News (2)

ERM CATALOGUE (4)

Factory Photos (3)

Products Description (7)

Company information (5)

Technological (4)

Foreign branch (1)

Credit Report

Products Index

Products Description

New design oil seal for high speed motor of soy milk maker and juice extrator

New design oil seal for high speed motor of soy milk maker and juice extrator

Soy milk maker and Juice extrator are 2 papular household applicance all over the world ,due to it can make fresh . Healthy ,axenic drinks .

But For the machine, motor and seal are very important . When the motor works , shaft speed will reach 20000 r/m to 30000 r/m , it is a very high speed . That means seal is very very important between motor shaft and container .

First Generalation of seal is used a silicone gasket . Gasket is Static seal, it can't used for rotating shaft . Also Silicone is not a good material to seal waters, when working under steam , silicone will be easy to expand , lead to leaking of machine ..

Second Gerneration , almost manufactuer use skeleton oil seal, and also choose a good rubber ( fluoroelastomer ) , some company used Viton of Dupont's brand instead of FPM rubber .

Rotary Shaft Seal is right and good design for this motor shaft , FPM material also is suitable rubber for high speed motor. So far , Fluororubber oil seal is a standard parts for soy milk machine and Juice Extrator.

But , This seal is still not the perfect . There are some deficiency

1) Fluororubber have a good property of wear resistant and high temperture resistance . However . Viton is still have a big wear loss , due to Shaft speed reach 30000 r/m or more , and viton rubber is not good of self lubricating .

2) In order to improve wear resistance. Some seals manufacturer will add more and more lubrication material into viton . That make the viton much better of wear resistance .but it lead to another problem . Viton rubber become not easy to bond with iron skeleton, bonding strength will be reduced . That there is a potential problem . When shaft working , Rubber is break from the skeleton ,then lead to leaking .

About this problem , it is not easy to find out the problem when Machine factory's QC inspect the goods from Seal supplier .

3) In order to improve the lubrication of seal , many factory will inject some lubracating oil .

Some Famous manufacturer will use food grade lubracating oil , but some factory use industrial oil . That is not safe for health .

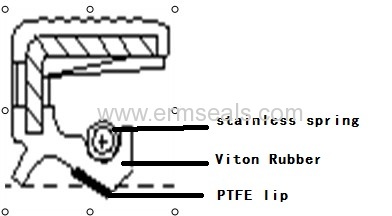

ERM sealing industrial limited company research and design a new oil seal for Soy milk maker and Jucie extrator. We bond a modified PTFE lip on viton oil seal . (see the picture)

1) modified PTFE is much better of ware resistance and lower friction factor than Viton.

That make the seal reduce the abrasion loss, and Extended Machine Life , Low friction factor will be improve self lubrication, it don't need to inject lubrication oil . Of course there are no oil pollution .

2)This new design of oil seal , doesn't be changed of style . It Inherits the advantages of the previous generation. Also Machine manufacturer don't need to change any size of existing parts of soy milk maker ..

New design of oil seal Section

Next Page:

PTFE gasket